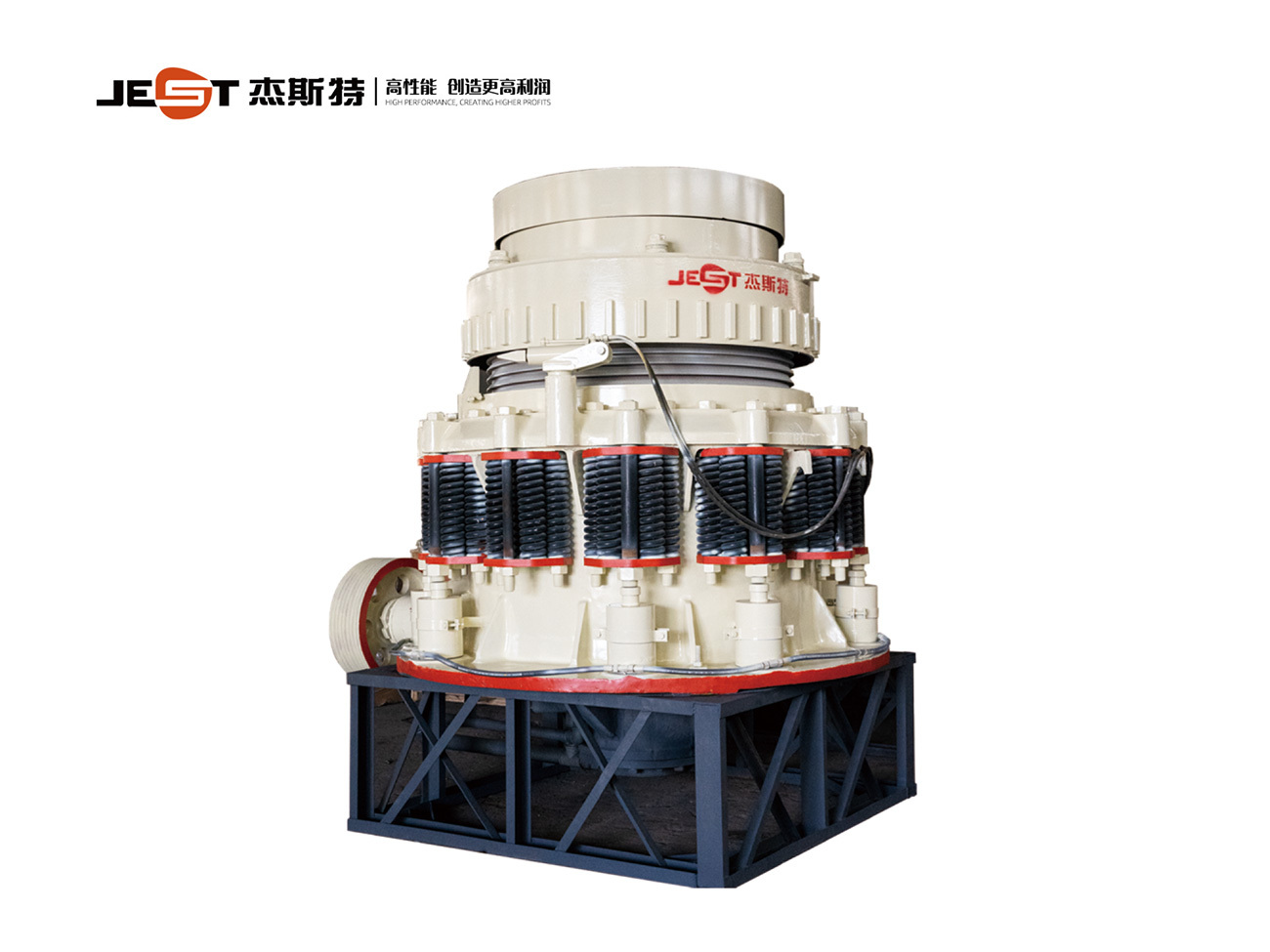

Product Introduction

JS series high-energy cone crusher is a modern high-performance crusher designed and developed by our company based on the principle of laminate crushing and the concept of more crushing and less grinding according to customer needs on the basis of introducing and absorbing advanced technology of cone machine at home and abroad, and integrating high swing frequency, optimized cavity type and reasonable stroke. It has the characteristics of reliable structure, high production efficiency, convenient adjustment and economical use.

JS series high-energy spring cone crusher takes the spring safety system as the overload protection device, which can make the metal foreign matter pass through the crushing cavity without harming the machine, and adopts the labyrinth sealing form to isolate the stone powder from the lubricating oil and ensure reliable work. It is widely used in sand and gravel aggregates, metal and non-metallic minerals, cement plants, construction, metallurgy and other industries, granite, limestone, quartzite, sandstone, pebbles, etc.

Features & Benefits:

1. The chassis has high strength, beautiful appearance and durability.

2. The control system of large-diameter spindle, heavy-duty main frame and independent thin oil lubrication system is sturdy and reliable.

3. The iron protection device ensures that after the miscellaneous iron passes through the crushing chamber, the original discharge port can be quickly restored to ensure the size of the discharge

4. The machine adopts the principle of lamination and crushing to form a protective layer of the material layer, which not only effectively reduces the wear, but also significantly increases the proportion of the neutral cube of the product.

5. The tooth plate is free of filling, and it is easy to replace. The mortar wall and crushing wall, the assembly surface is specially designed and precision machined on a special machine tool

6. Semi-automatic, hydraulic adjustment discharge port can effectively control the particle size of sand and stone, fast and convenient.

7. The special crushing chamber design greatly improves the production capacity.

8. Labyrinth combined, grease sealed, good dust-proof effect.

9. The lubricating oil circulation cooling system is simple and efficient, and the temperature control system and pressure control system detect and protect the host in an all-round way.

10. Bevel gear transmission, strong and stable.

11. The copper sleeve produced by special formula and special process is durable.

12. Small size, light weight, reasonable structure.

Technical Parameters:

| Parameters/models |

JS1218 |

JS1423 |

JS1525 |

JS1730 |

JS1835 |

| Crushing Cone Nominal Diameter ( Inch ) |

48″ |

54″ |

60″ |

66″ |

75″ |

| Maximum feeding size(mm) |

180 |

230 |

250 |

300 |

350 |

| Discharge port adjustment range (mm) |

10-38 |

13-51 |

16-64 |

19-70 |

22-100 |

| Processing capacity (31.5 or less finished products) ( t/h ) |

90-110 |

150-180 |

200-250 |

220-300 |

250-400 |

| Throughput ( Throughput ) ( t/h ) |

78-280 |

160-480 |

235-640 |

300-700 |

400-1200 |

| Motor power(kw) |

132 |

185-220 |

220-250 |

250-315 |

315-355 |